In addition to the above, visual observations on mechanical

components is very important. The possible cause for each

item is explained below.

Header / manifold

Generally this is made with steel or uPVC. The main problem which can occur in the manifold is water

leaking through the joint. If this happens, tighten up the relevant joint. If there are any main repairs

required, it is better to do this using new packing material (in other words do not re-use packaging

material). In addition, paint this part to protect it from corrosion.

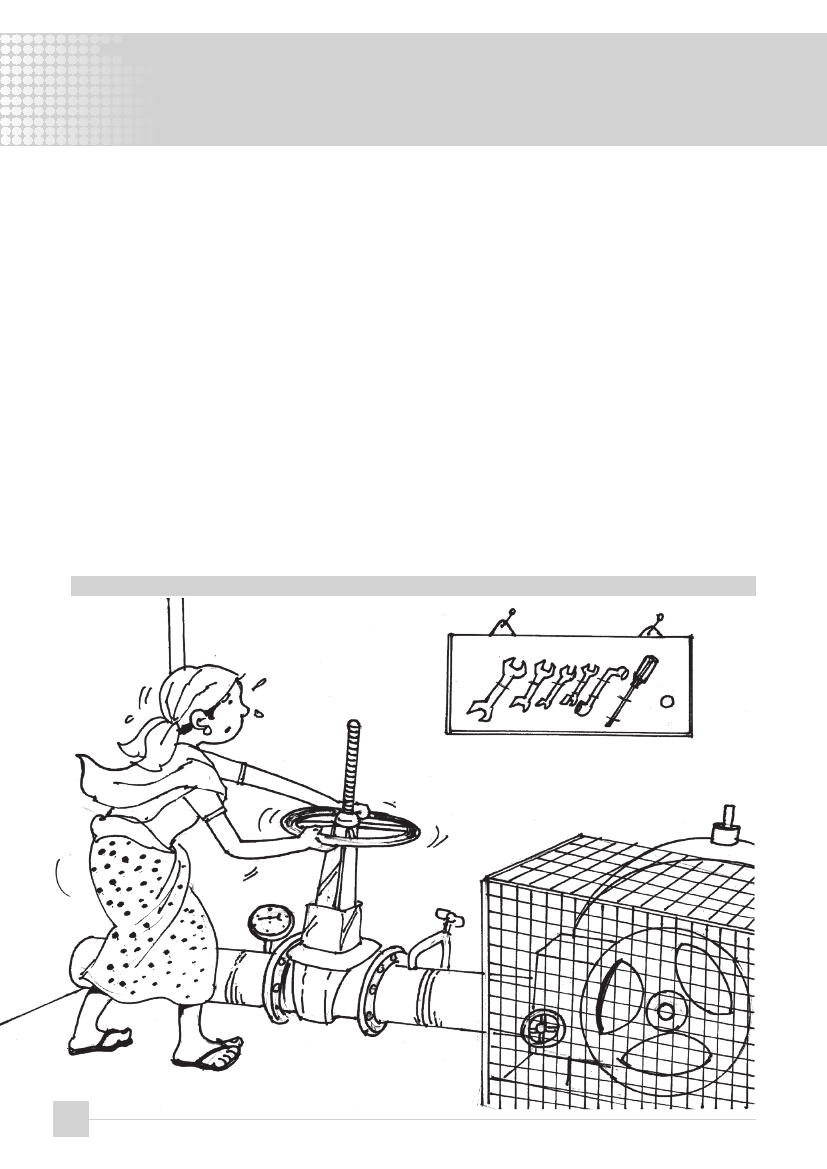

Valves

According to design of the turbine it may have one or more number of valves. The most common

problem that occurs with valves is that water leaks through a worn out valve shaft. If there is a water

seal tightening arrangement, the valve can be tightened to stop the water leak. If it leaks again after

sometime it has to be further tightened.

In addition, if some particles come with the water (due to improper filtering) this may block the valve.

This problem can be identified by the tightness of the valve and difficulty in fully closing the valve. In

such a case, the valve has to be taken out and the particles removed.

Whenever the turbine is stopped do not tighten the valve too much. This can lead to the seating surfaces

of the valve being worn out quickly.

Tightening the valve

16